Ventilation Control System

Laboratory is the specific environment used to accomplish varieties of experiments. Laboratory airflow control system is vitally important for ensuring the safety of doing experiments, so it's necessary to ensure that the poisonous gas can discharge through the fume hood, maintain the proper pressure in the lab, and establish a safe and comfortable working environment.

Mail Purpose of Lab Air Flow System

Operator safety: to consider catching and preventing from harmful gas

Room pressure: to keep the right air flow direction

Ventilation: to provide the appropriate air changing

Comfortable: to provide the appropriate control of humiture

Ventilation Control System

Sectional type variable frequency system

Constant air volume system

Two-state stable system

Variable air volume system

Adaptive Control

The Choice of Ventilation System

If properly designed, CAV or VAV system can provide users the required security and environmental comfort. In terms of the type of ventilation system (CAV or VAV), owners' first consideration is the initial investment, operating cost, maintenance cost, expansion cost and choosing the most suitable system. But given the long-term operating cost,the initial investment of VAV system may be slightly higher than CAV systems,but it' s also the best choice.

VAV Control System

VAV System is able to meet the needs of the whole lab pressure, each room pressure, air volume,and humidor etc., and reduce power consumption.

To provide safe and comfortable environment, reduce the users' pre-investment and the fee of running, energy consumption and maintenance and so on. Its technology ensures the rapid reaction and safety; with the high accuracy, it controls the Fume Hood face speed and the inner pressure to provide the best stability.

Its control principle bases on the amount of airflow. It can precisely control air volume inaccordance with the actual need.

In this way, users would not need too much equipment, too much air-conditioning and ventilation capacity, without regular maintenance.

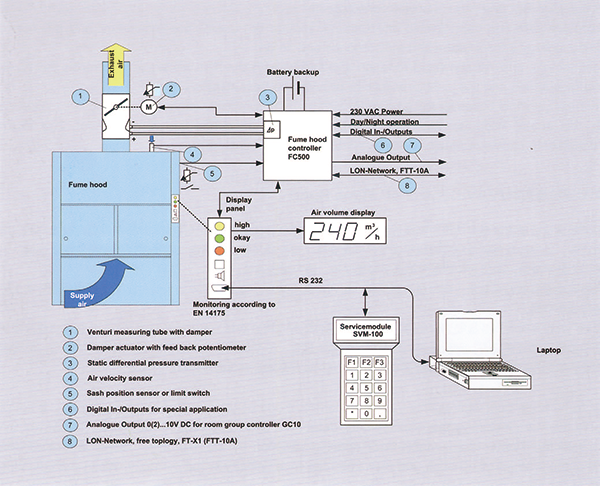

VAV Control of Fume Hood

VAV fume hood control is mainly using the control mode of VAV setting the face velocity.

It adopt double manners including the displacement detection" and "face velocity detection" to control the face velocity.

It detects adjustable door opening variation by the manner of displacement sensor, control the amount of exhaust, and then keep the face velocity in the set point.

When the adjusting door at the same position, the sensor measures faces velocity and has the precise adjustment.

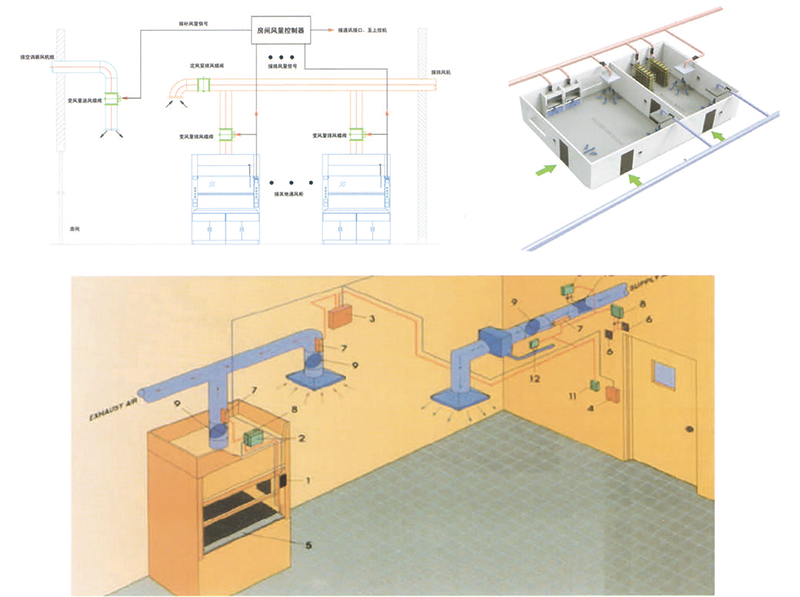

Residual Air Volume Control in the Negative Pressure Room

Depending on the experimental conditions of the laboratory, we should consider the different pressure. In order to prevent the spread of pollutants and ensure the safety of the surrounding environment, if the ordinary laboratory wants to achieve the slight negative pressure, it mainly needs the rational design of ventilation systems of lab and automatic control system to achieve.

In lab, it usually adopts the negative pressure and air volume control in room. In real-time, it calculates and analysis the total exhausts volume from the exhaust of all the VAV equipment and exhaust ventilation equipment in the room, and adjusts the room into the fresh air. It makes the air volume form a constant difference value.

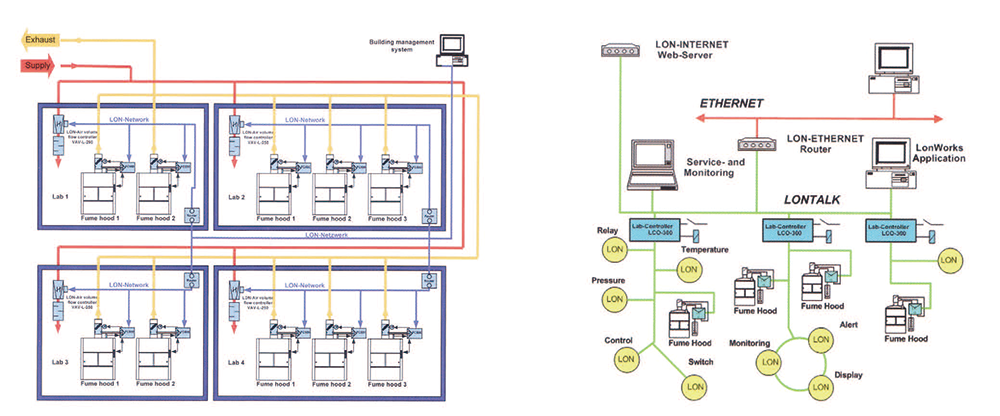

BMS Central Monitoring System

By means of "Lon Works@ technology”, Laboratory airflow control system make VAV fume hood and its corresponding VAV exhaust valve and fill valve be connected into a room-level subsystem. The subsystem in the room-level system are connected to the gateway through a router, and thus forming a fully functional building-level control system.

New air's handling units and the corresponding exhaust fan should be adopt a control system and provide the control cabinet with Power distribution which is installed in the floor. The control cabinet with Power distribution should have manual and automatic control systems. All electrical controls are included in the control cabinet. When opening a new air handling units, corresponding exhaust fan should be open simultaneously. Set the switch and the corresponding status indicatoron the front panel.

Each laboratory is an independent subsystem through the router, and all subsystems can be connected to the upper computers via twist-pairs, which can make the remote monitoring work.

Supply/Exhaust Pipeline System

Hanguang—Professional Design of Ventilation System

We design the most adaptable lab ventilation system according to different industry laboratory and customer needs;Ventilation professional design team, strict compliance with industry standards, to provide the most professional design scheme for customer.

Ventilation Pipeline

Material of ventilation pipe: PP/PVC/PPS/inorganic glass steel/organic glass steel/ stainless steel /galvanized steel.

Each laboratory exhausts different gas components. Thus we should take into account these factors (such as: high temperature resistance, corrosion resistance, durability, safety and cost) to select the material of the pipes, which can ensure laboratory gas can be effectively discharged. For some anti-explosion and the special requirements for laboratory, the material of pipes should be carefully chosen.

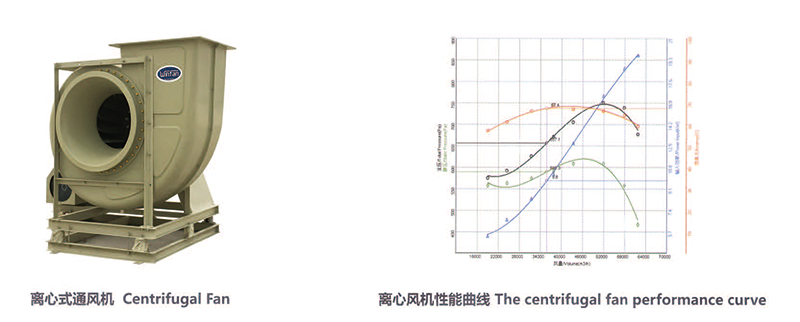

Fan

There are mainly two types of fans in lab,such as: centrifugal,axial flow,etc. selecting the type of fans should be based on these characteristics: good aerodynamic performance, smooth operation, small vibration, high efficiency and long life.

Centrifugal fan can delivery air and other gas which is non-pyrophoric,harmless for people, and non-corrosive to steel. This type fan has been widely used in lab indoor ventilation.

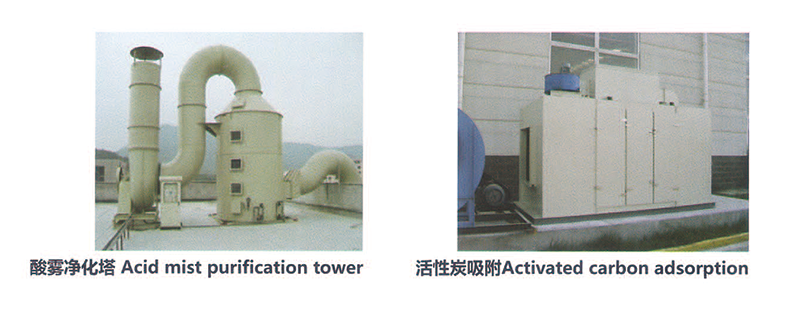

Waste Gas Treatment

The main air pollutant in laboratory is including organic gases and inorganic gases. Currently the treatment of gaseous pollutant can be divided into two categories: the wet: the treatment of acid mist purification tower; the dry: Activated carbon adsorption of pollutants.

The theory of acid mist purification tower is that the exhaust gas is pressed into purification tower through the fan, goes through the spray and the filler layer; after purification of exhaust gas, and then was treated by removal off liquid layer, and then discharged into the atmosphere.

Activated carbon adsorption unit commonly used exhaust treatment in laboratory. It has these features: Large surface area,the drag coefficient, absorption speed, high efficiency, simple and quick in desorption.